Drilling and blasting form the backbone of modern mining. Whether it’s a large opencast metal mine, a limestone quarry, a coal overburden operation, or an underground hard-rock mine, almost every ton of rock produced today is broken using drilling and blasting.

What is Drilling and Blasting in Mining?

Drilling & Blasting is a mechanical + explosive process used to break rock into a workable size.

The sequence is simple:

- Drill holes in the rock

- Fill them with explosives

- Initiate them safely

- The blast fractures the rock

- Load → Haul → Crush → Process

Mining without drilling and blasting is impossible in hard rock. Even in soft rock, drilling & blasting reduces cost and improves fragmentation.

Importance of Drilling & Blasting

Mining productivity depends directly on drill & blast quality:

- Better fragmentation → faster loading

- Less oversized → better productivity

- Controlled vibration → safer blasting

- Correct drilling → reduced explosive consumption

- Proper spacing → uniform breakage

- Ideal burden → safe energy release

Even a small drilling error can destroy an entire blast pattern.

Types of Drilling Used in Mining

A) Rotary Drilling

Uses rotation to cut rock.

Used in:

- Large opencast metal mines

- Soft formations

- 150–350 mm holes

Advantages:

- High rate of penetration

- Very large diameter holes

B) Percussive Drilling (Hammering Action)

This type breaks rock by repeated hammering.

Types:

- Top Hammer (TH)

- Good for short holes

- Used in small quarries

- Down-The-Hole (DTH)

- Hammer is directly behind bit

- Deep, straight holes

- Most popular in limestone & stone quarries

Why DTH is important?

✔ Minimal deviation

✔ High accuracy

✔ Uniform fragmentation

C) Jumbo Drilling (Underground)

Used for tunneling & development headings.

Comes with 1–3 booms, allowing multiple holes in one setup.

Applications:

- Drivage

- Shaft sinking

- Long-hole blasting

- Production stoping

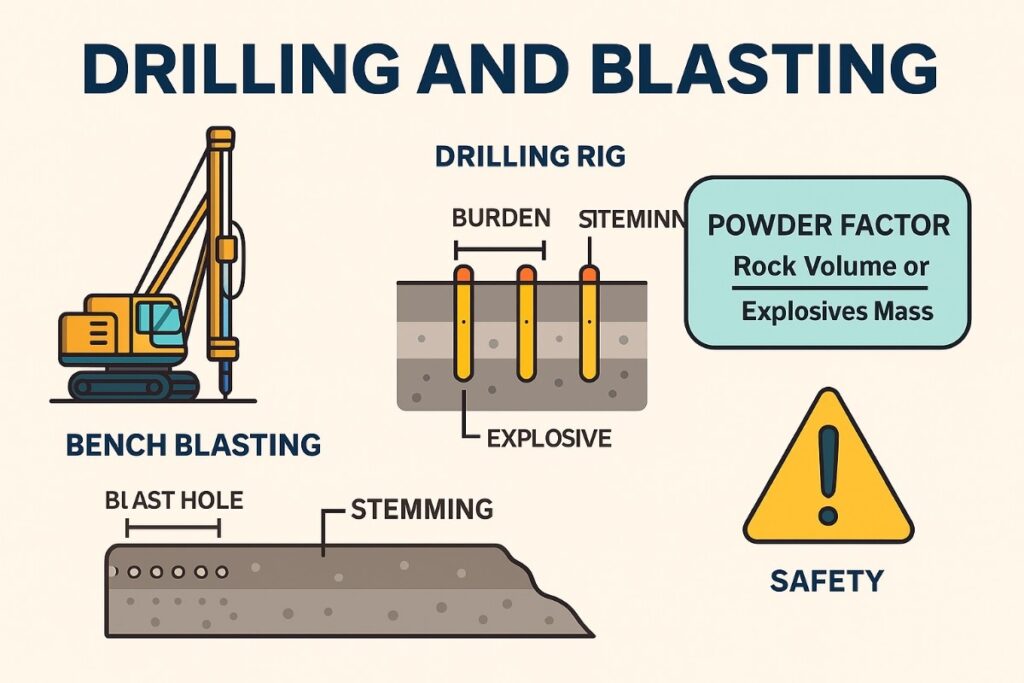

Key Drilling Parameters (Exam + Field)

| Parameter | Meaning |

|---|---|

| Burden (B) | Free face se first hole tak distance |

| Spacing (S) | Hole-to-hole distance |

| Bench Height (H) | Floor to free face height |

| Sub-Drilling | Extra depth for full toe breakage |

| Stemming | Inert material above explosive column |

| Charge per Hole | PQ × Density × Hole Volume |

Typical Ratios

- Spacing = 1.2–1.5 × Burden

- Stemming = 0.7 × Burden

- Sub-drilling = 10–30% of hole depth

Explosives Used in Mining

1. ANFO (Ammonium Nitrate + Fuel Oil)

- Most common

- Cheap

- Easy to load

- Not water-resistant

Used in:

- Dry holes

- Bulk blasting

- Surface mines

2. Slurry Explosives

- Water-resistant

- Good for wet holes

3. Emulsion Explosives

- High velocity of detonation (VOD)

- Best for hard rock

- Very good water resistance

Used in:

- Granite mines

- Metal mines

- Underground charging

4. Cartridge Explosives

- Gelatin / permitted explosives

- Underground fiery mines

- Small diameter holes

Initiation Systems

A) Detonators

- Electric

- Non-electric (NONEL) → industry standard

B) Detonating Cord (Det Cord)

Used for surface connections.

C) Delay Systems

- Short delay

- Long delay

- Electronic delay → highest accuracy

Delays help in:

✔ Fragmentation

✔ Vibration control

✔ Reducing flyrock

Blasting Patterns

Surface Mines

- Square

- Staggered (most efficient)

- Line drilling

- Pre-splitting

- Buffer blasting

Underground Mines

- Burn Cut

- V-Cut

- Fan Cut

- Pyramid Cut

- Parallel Cut

Blasting Problems & Their Solutions

| Problem | Cause | Solution |

|---|---|---|

| Flyrock | Overcharging | Reduce charge, increase stemming |

| Overbreak | Excess energy | Controlled delay & charge |

| High vibration | Large MIC | Reduce charge per delay |

| Air blast | Bad stemming | Use proper stemming material |

| Misfires | Poor connection | Proper testing & DGMS checklist |

Important Formulas (Exam Use)

Powder Factor (PF):

PF = Rock broken (tons) / Explosive used (kg)

MIC (Maximum Instantaneous Charge):

MIC = Charge fired in one delay

Stemming Length:

≈ 0.7 × Burden

Sub-drilling:

≈ 0.2 × Hole depth

Conclusion

Drilling and blasting are the heart of mining operations.

Performance of the entire mine — from loading to hauling to crushing — depends on how well the drilling & blasting is done. This is article uses for the exam of Mine Supervisor and Royalty Inspector for mining and geology aspirant.

A drilling mistake = a blasting disaster. A blasting mistake = a production disaster.

About the Author

Navin Solanki is a Mining Engineer with over 5 years of practical experience in the Indian mining sector. He focuses on mining operations, geology, environmental studies, and regulatory topics in India. [Read More]